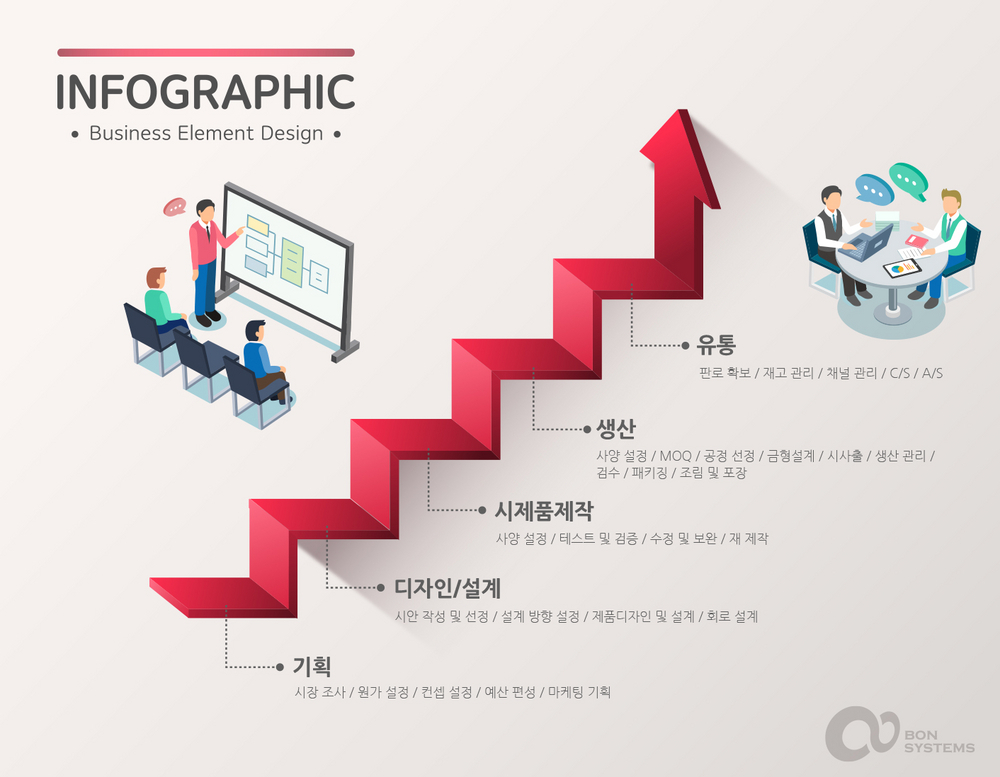

Among the methods for improving productivity of the product, we introduce a small amount of injection of plastic products using simple molds. The above method, which can dramatically reduce mold and lead time in the manufacturing process, is used as one of the ways to improve product productivity in many industrial sites, including large companies and startups.

1. Significance of shortening production lead time Various factors must be considered to reduce the time required for the production process.Reducing the time spent during the manufacturing process can help reduce costs and improve performance through orders and sales.They often deviate significantly from their original expectations ahead of the launch of new products. This increase in lead time, especially for products targeted for a specific period or season, can hurt a company’s sales.

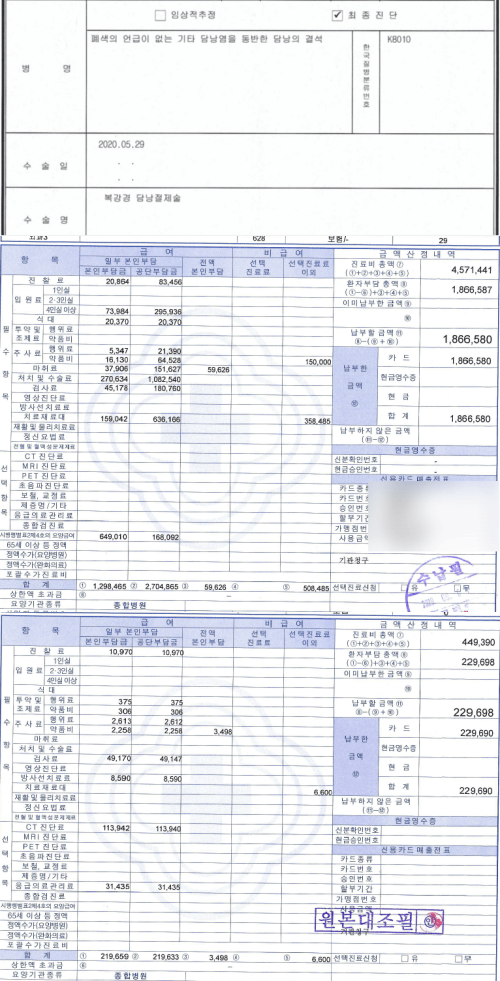

Before deciding how to shorten the manufacturing process, various measures may be applied depending on whether the product is being released or mass-produced.This article introduces how to shorten the lead time and characteristics of plastic products using the observation method that can be used when small production of 100 to 3,000 units is required to verify and secure the marketability of products before mass production.The method I will introduce is advantageous for situations where the production system has not yet been established or for short delivery times. I would like to explain the related contents in detail in the following sentence.

Before deciding how to shorten the manufacturing process, various measures may be applied depending on whether the product is being released or mass-produced.This article introduces how to shorten the lead time and characteristics of plastic products using the observation method that can be used when small production of 100 to 3,000 units is required to verify and secure the marketability of products before mass production.The method I will introduce is advantageous for situations where the production system has not yet been established or for short delivery times. I would like to explain the related contents in detail in the following sentence.

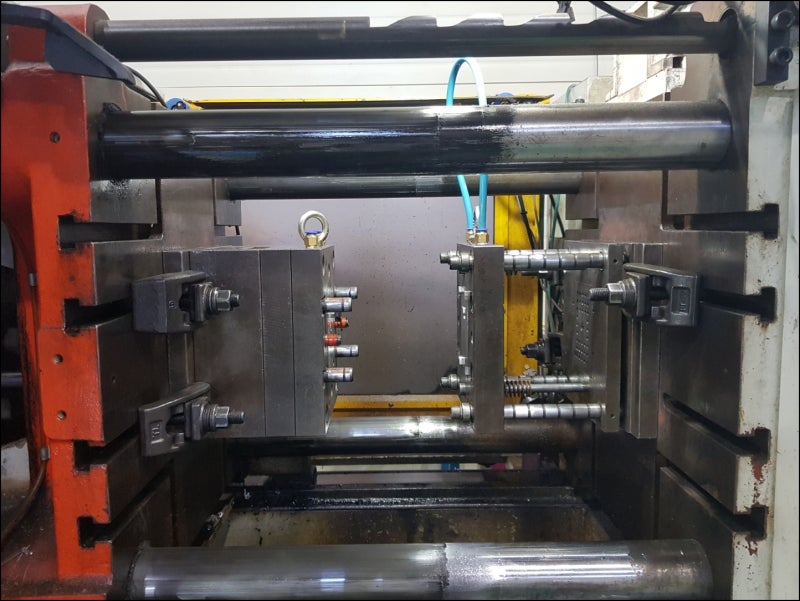

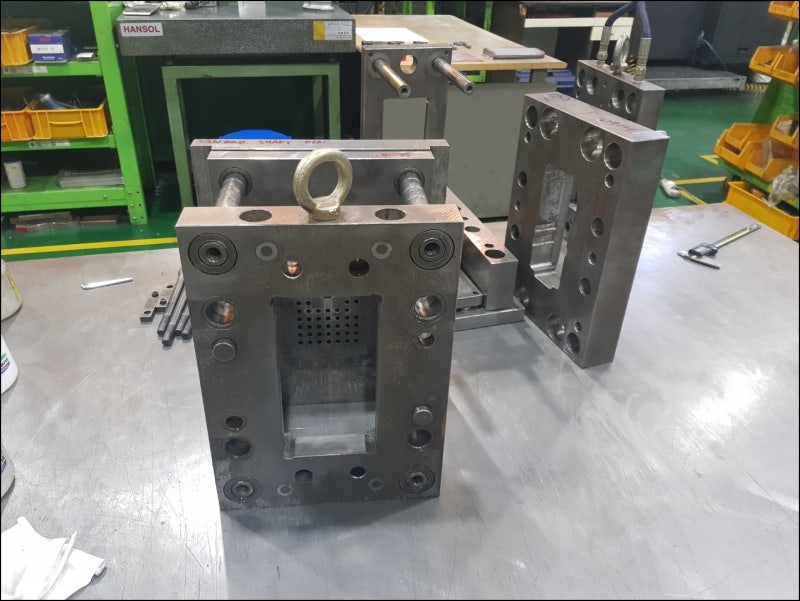

2. Characteristics of QDM molds It is an injection molding method that produces plastic products by processing only a separate core and cavity using Mold Base, which is standardized by the abbreviation Quick Delivery Mold.Please understand that if the general mass production mold is custom-made, QDM uses ready-made products. The reason why this method can contribute to improving merchant ships and shortening lead time for products in the production process is that the time required for mold production is greatly reduced.

Generally, mass-produced molds take an average of more than a month from design to processing. On the other hand, the simple mold uses an already completed mold base, which can shorten the time required in the mold manufacturing process. On average, the molds on the inner and outer surfaces are completed for two weeks.Instead, the initial injection unit price is measured higher than mass production, so it is not suitable for making a large number of products. Although it has the advantage of being able to produce plastic products in a short period of time, it is inappropriate to use them simply for the purpose of reducing lead time in the manufacturing process.

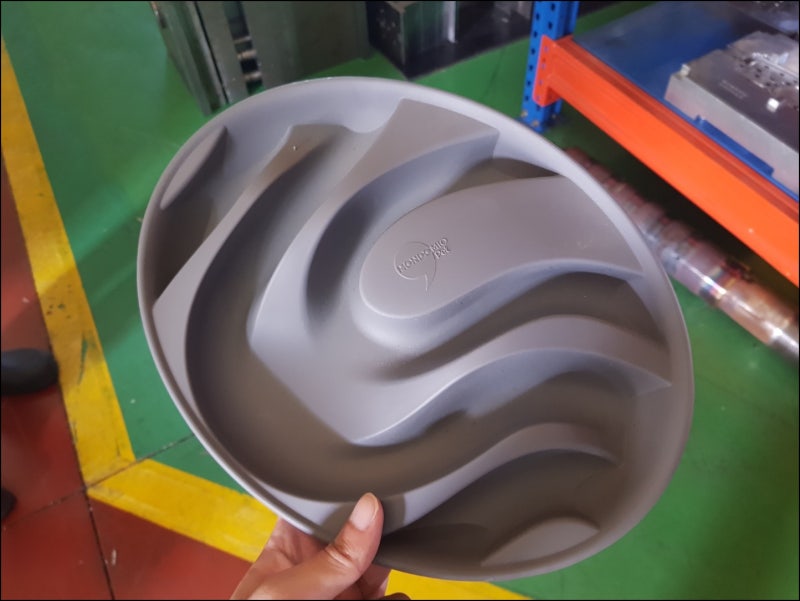

In order to reduce costs, it is desirable to manufacture mass-produced molds, but it is recommended to use this method when it is burdensome to secure large inventories in a situation where annual sales volume is limited and marketability is not clearly verified. 3. Under the manufacturing example, I will end this sentence with an introduction to the production of plastic products using QDM molds. If you have any questions or questions about production, please visit our website and provide basic information such as materials and quantities along with CAD data to support consultation after checking the contents.Previous image Next imagePrevious image Next imagePrevious image Next image